XZS-Series Rotary Sifter/Rotary Sieve Machine

Description

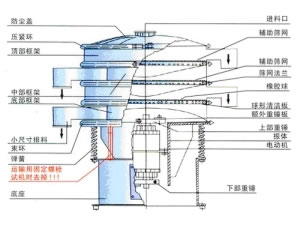

Rotary sieve machine, often called rotary sifting machine, is a new high precision fine powder screening machine. It uses vertical vibration motor as excitation source. This motor is equipped on both sides with an eccentric hammer which functions to transfer the rotation movement of motor to horizontal, vertical and inclined motions. And the hammer then delivers the motions to screen surface for sifting. At present, rotary sieve machine is widely applied in pharmaceutical, foodstuff and other industries.

Applications

Rotary sieve machine is suitable for many industries.

1. Chemical industry: resin, paint, industrial pharmaceuticals, cosmetics, herbal powder, etc.

2. Food Industry: sugar powder, starch, salt, rice flour, milk powder, soybean milk, egg powder, soy sauce, juice, etc.

3. Metal and metallurgy mining: aluminium , lead, copper, alloy and solder powder, ore, manganess dioxide, electrolytic copper powder, electric magnetic materials, grinding powder, refractory materials, kaolin, lime, alumina, heavy calcium carbonate, quartz sand, etc.

4. Pollution treatment: waste oil, waste water, dyeing wastewater, additives, activated carbon, etc.

Trajectory Graph of Rotary Sieve Machine

| Flow Direction of Material | Angle of Hammer | Effect | Usage of Rotary Sifting Machine |

|

|

Raw materials flow along the peripheral direction | Coarse screening |

|

|

Beginning of spiral movements | General sifting |

|

|

The longest vortex motion | Precise grading of micro powder and materials with high coherence and high moisture content. |

|

≥100°  |

Raw materials are gathered at the centre. | Special purpose |

Features

1. Rotary sieve machine has features of small size, high efficiency, simple operation and small size. With high screening precision, it is suitable for all kinds of powdery and mucus materials.

2. This rotary sifting machine is removable and only takes 3 to 5 minutes to change a net.

3. Its screen is not blocked and produces little scattering dust. It can sieve 0 to 400 meshes of materials.

4. Rotary sieve machine is well-designed and durable, which can work continuously.

5. During the sieving process, coarse materials and impurities can be discharged automatically. The discharging direction can be adjusted along the circumferential direction.

6. Rotary sifting machine can sieve materials on different layers (not more than 5) at the same time.

Parameters

Following data function as reference for selecting the most appropriate model of rotary sieve machine.

| Model | 600 | 800 | 1000 | 1200 | 1500 | 1800 | 2000 | |

| Diameter of Effective Screen (mm) | 540 | 730 | 900 | 1100 | 1400 | 1700 | 1886 | |

| Effective Sifting Area | 0.2281 | 0.4183 | 0.6359 | 0.9499 | 1.5386 | 2.2687 | 2.7922 | |

| Screen Specification (Meshes) | 2-500 | |||||||

| Number of Plies | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-3 | 1-3 | |

| Power (Kw) | Vibration Motor | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 3.0 | 3.7 |

| Ordinary Motor | 0.75 | 1.1 | 1.5 | 1.5 | 2.2 | 2.2 | 3.0 | |

With about 20 years’ development, Shanghai Lanteky has become a professional and one of the leading suppliers of pharmaceutical machines in China. Throughout these years, the company has always encouraged innovation and developed new technology to improve the quality of products (e.g. rotary sieve machine). Besides, our company also devotes itself to providing comprehensive customer services like machine selecting, technical designing, technique training, customization, and so on. For more details about rotary sifting machine, please visit the company’s website or contact us directly.

- Model XZS Vibrating Sieve MachineVibrating sieve machine, also called spiral vibrating screen, is basically made up of charging tray, shaking chamber, coupler and engine base. Its adjustable eccentric hammer revolves with the driving motor and produces centrifugal force which drives materials to spiral in the sieve. It can ...