Powder Sieve Machine/Sifting Machine

Model XZS Vibrating Sieve Machine

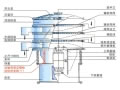

Vibrating sieve machine, also called spiral vibrating screen, is basically made up of charging tray, shaking chamber, coupler and engine base. Its adjustable eccentric hammer revolves with the driving motor and produces...

XZS-Series Rotary Sifter/Rotary Sieve Machine

Rotary sieve machine, often called rotary sifting machine, is a new high precision fine powder screening machine. It uses vertical vibration motor as excitation source. This motor is equipped on both sides with an eccentric hammer...

Description

Lanteky powder sieve machine, also called sifting machine, is mainly used for dealing with industrial materials. It has two sieves--one is coarse mesh and the other is dust separating mesh. Both sieves are necessary in the sifting process. Its shaking part and pedestal are connected and fixed by 6 sets of soft rubber shake absorbers. These absorbers are controlled by the adjustable eccentric hammer. At present, powder sieve machine is an ideal facility for sifting tablets and powders used in the industry of medicine, chemicals and food.

Classifications

Powder sieve machine can be classified into two series:

1. XZS Vibrating Sieving Machine

This powder screen is mainly used to sieve powdery and granular materials continuously in cosmetic and pharmacy industries.

2. XZS Rotary Sifting Machine

This type is famous for the horizontal, vertical and inclined motions. It is suitable not only for granules and powders but also mucilage.

Applications

Powder sieve machine is suitable for a number of industries, including pharmacy, food, ink, construction, resin, cosmetic and chemical industries.

Features

1. Powder sieve machine features high efficiency, precise fineness, low energy consumption, simple operation and small size.

2. Such sifting machine is well-designed and can work continuously, suitable for various powdery materials and mucilage.

3. It produces little noise and is easy to maintain, thus environmentally friendly and economical.

4. Powder sieve machine can be used with a variety of mills.

5. The screen is installed vertically without a weight, thus durable. And it is easy to change and clean. It has at most 400 meshes, thereby productive.

6. With a special screen frame design, the change of screen takes only about 3 to 5 minutes.

7. Stainless steel is adopted to avoid abrasion and corrosion.

8. Powder sieve machine works under the condition of negative pressure and semi-cycle, which is non-pollutant.

9. With this machine, impurities and coarse materials can be discharged automatically.

10. Powder screen can also be customized for special requirement.

Maintenance

1. Powder sieve machine should be started when there are no materials on the screen surface. And do not fill objects until it runs smoothly.

2. Stop filling materials before closing the sifting machine.

3. Examine regularly the operation condition. Stop it for inspection and debugging if abnormality or strange sound is found.

4. Powder sieve machine uses No. 2 lithium base lubrication grease. Normally, refill grease every 2 months but do not refuel too much to avoid overheating of bearings.

5. Check grease after 6-month working of the machine. If there is a lump, please clean it and change with new grease.

6. Bearings of powder screen are expected to be washed once a year.

Located at Dongjing town, Songjiang district of Shanghai, Shanghai Lanteky has a land and factory with over 50 workers who are experts. At present, the company mainly manufactures and sells 10 series of about 40 kinds of machines, like tablet press, grinder, mixer, granulator, oven, powder sieve machine, etc. And the company enjoys great convenience of transportation because it is not distant from Shanghai Port. This geographical position also brings down costs and provides a larger market and a lot of developing opportunities. For more information, please visit the company’s website or contact us directly.